404 - Content not found

And now?

Use the search box above or contact us via our contact form.

You might also be interested in

-

Circular knives

Learn moreWhether made of steel, powder metallurgical steel (DPM), carbide, special materials or refined – our circular knives always stand for perfection. In up to 40 operations, we use the latest technology to produce highly effective products that impress with precise and clean cutting edges in long-term use.

-

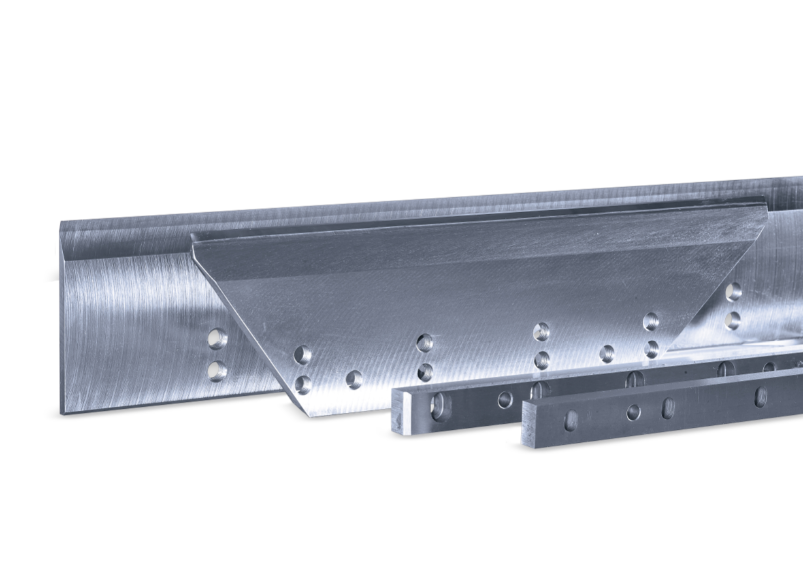

Straight knives

Learn moreThe DIENES standard programme, developed with know-how, includes a wide range of paper and foil knives, recycling knives, shear blades, perforating knives, profile knives and shear and crap chopper. The straight knives are available up to a length of 6,000 mm and with matching cutting sticks and folding tools.

-

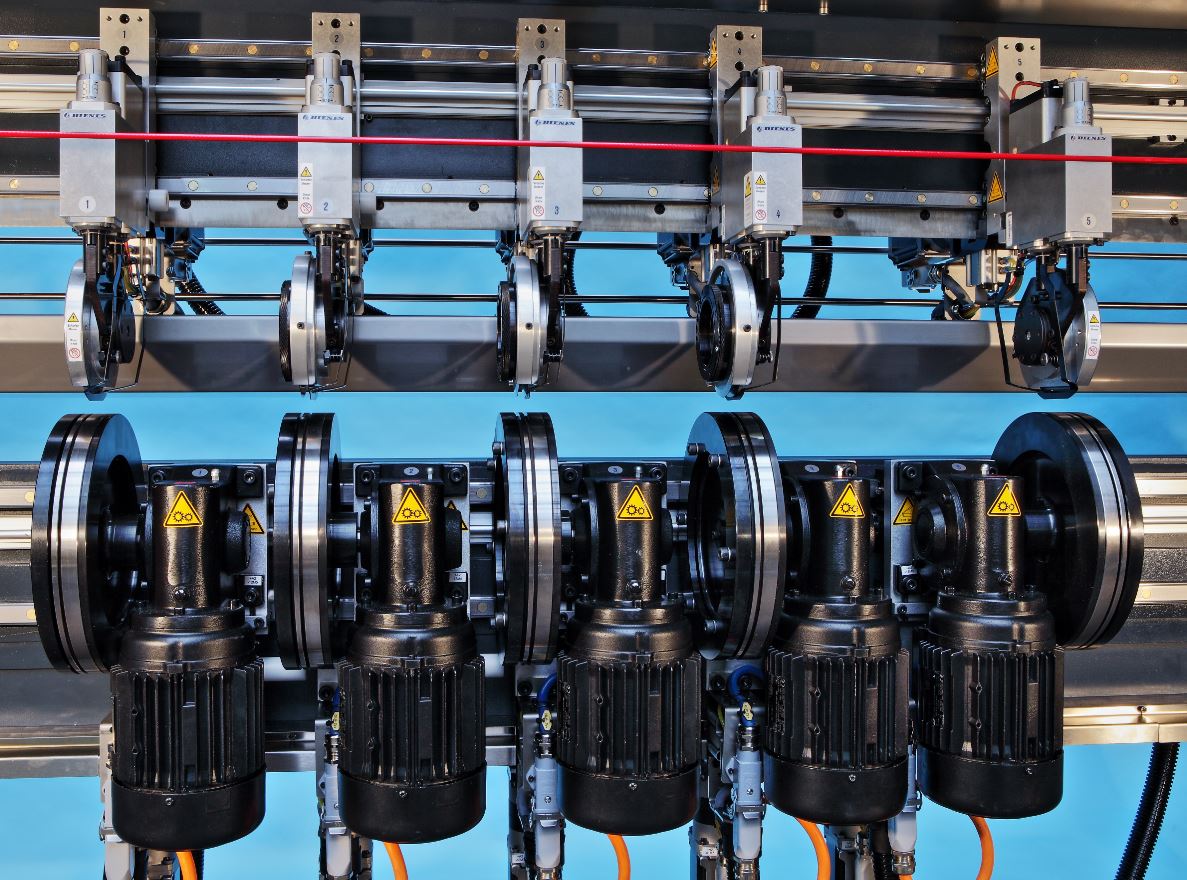

Knife holder

Learn moreWhether shear cut, crush cut, burst cut/razor cut knife holder or hot cut holder, whether from the Premium, Elite or Ultimate series – they all convince with the most precise knife guidance, long service life, simple operation and secure hold in daily use.

-

Slitting systems

Learn moreWe offer you economically efficient standard solutions as well as customised special optimisations specifically tailored to your areas of application. Our slitting systems with circular and straight knives, for sheeters/equipment (up to 1,000 g/m2), bobbin slitters, narrow and large reel slitters / carrier and support rollers (up to 3,100 m/min) are available as ready-to-plug-in systems for retrofitting or completely assembled and harmoniously integrated.

-

Slitting academy

Learn moreAs an innovative pacesetter and market leader for industrial slitting solutions, we feel obliged to offer our customers not only optimal products, but also the best possible service. And this also includes our know-how transfer, which we make available to you under the umbrella of the DIENES SLITTING ACADEMY.

-

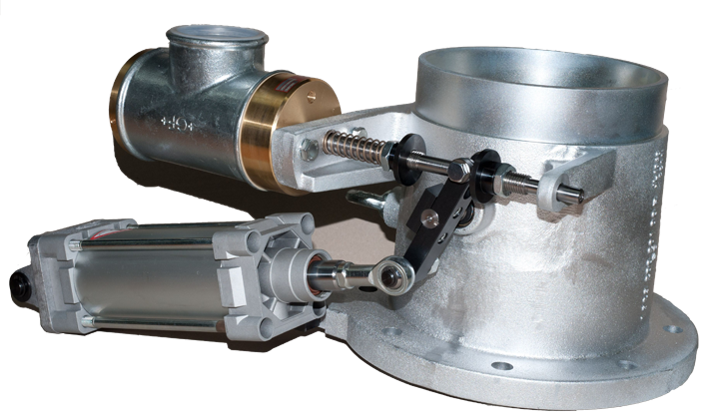

Valves

Learn moreAll DIENES valves are manufactured using optimised production processes and under constant quality control. Design and execution are created in close cooperation with our customers in order to achieve the best possible functional behaviour of the entire compressor for the customer-specific application and to continuously improve the products.