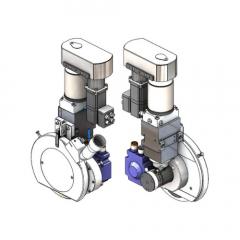

Roll stands

Rolling stands, also known as mill stand, are a component of so-called rolling mills and are used to reduce the thickness of various materials, such as sheet metal, aluminum or steel. In this context, roll stands can differ in terms of the type and number of stands, as these are always adapted to the prevailing production conditions.

DIENES know-how

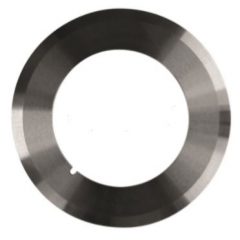

Rolled materials must also be shaped into the desired form in order to subsequently become the finished end product. This is where our cutting tools come into play. Leave nothing to chance and rely on our expert knowledge. In our cutting laboratory, we analyze the material to be cut and select or develop the optimum solution for you. This way you get the best possible cutting results and a high-quality end product.

Mode of operation

In the process of rolling, the material is passed between at least two work rolls. Within a rolling mill, there may be only one roll stand or several in series. This can help to achieve the desired material thickness, because it is technically not possible to feed the material into the same roll stand again. There are Duo,- Trio,- as well as Quatro stands, which differ accordingly by the number of rolls. Moreover, it is possible to process a material with the help of hot or cold rolls depending on its requirements.