Trimming Station

Equipped with high-precision DIENES cutting tools, we offer you, for example, trimming stations for cutting double-layer aluminum foil between 12-38 µm. In addition, we manufacture fully automatic trimming stations for plastic films, extrusion lines, calenders, laminating machines, manual trimming station (C-frame) and for cutting papers. Moreover, we supply electronically adjustable trimming lines with web edge detection for textiles and nonwovens.

DIENES know-how

DIENES trimming lines reduce your fabric loss, your set-up costs and at the same time offer long service life and low dust operation. On request, we manufacture manual or automatic edging stations, also with edge trim extraction. In addition to new machines, we also specialize in retrofitting existing machines.

Our goal is minimized set-up times and costs, low machine downtimes, fast format changes, easy handling and optimum trim edge quality.

Edge trim chopper

The outer right and left installed shear cut knife holders, so-called trimming holders, can be supplemented by an edge trim chopper on request. In this case, a pneumatic cylinder equipped with a cut-off knife is activated with a time delay after the longitudinal cut has already been made. In this way, the narrow waste strip is divided crosswise and can be disposed of via the respective suction hopper. We recommend that you vacuum the edge strip parallel to the running direction of the material web right after the cutting process. Abrupt changes in direction of the edge strip lead to fluttering of the strip to be cut off. Cracking and wavy cut edges are signs of uneven web tension.

The suction speed must be adapted to the material web speed. If the material to be cut is thick, too much suction will result in torn edges; if the material is thin, it will result in tears. The slitter section should be arranged in such a way that the shortest possible distances are maintained between the deflection shafts before and after the slitting station. In specific cases, it may be necessary to take additional measures here.

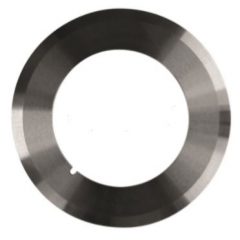

Complete collars with fixed or spring-loaded rotary shear knives can be used economically where wide strips are cut or where strips are trimmed. Here, the cutting tools, which can be set in any desired cutting position, give economic advantages due to the elimination of the intermediate rings otherwise used for adjusting the rotary shear knives, as well as due to reduced downtimes of the cutting line during program changes.

Matching DIENES products

-

![Circular knives - dished knives]() Circular knives

Circular knivesDished knives

Diameter 62-200 mmShow more -

![The goal of a DIENES knife is to achieve more performance, maximum tool life, minimum setup times and high cutting edge quality with minimum changeover effort.]() Circular knives

Circular knivesFlat top knives

Diameter 90-220 mmShow more -

![The picture shows DIENES grooved knives and multiple grooved knife blocks.]() Circular knives

Circular knivesGrooved knives

Diameter 46-250 mmShow more -

![DIENES multiple grooved knife blocks for an optimal cutting result.]() Circular knives

Circular knivesMultiple grooved knife blocks

Diameter 77-490 mmShow more -

![A DIENES bottom knife.]() Circular knives

Circular knivesBottom knives

Diameter 105-300 mmShow more -

![Shear cut pair of knives (collars) with knife carriers.]() Circular knives

Circular knivesCollars

Diameter 62-150 mmShow more