Adhesive tape and labels

Cutting materials coated with adhesives is part of everyday life in the processing industry and requires specially adapted solutions. When cutting adhesive tape, labels but also diaper closures, it is important to prevent the build-up of adhesives on the tools as well as the “bleeding” of the cut rolls.

DIENES Know-How

Today the pneumatic crush cut knife holders type PQDS and PQAS are worldwide established. They were invented and patented by DIENES in the 70s. In this process, the crush cut knife, which is guided in an air-operated knife holder, is pressed against a specially surface-hardened cutting shaft. At the point of contact, the material is separated by displacement. The cutting work can be adjusted as required and an uncomplicated, safe operation is ensured. The “bleeding” of the material to be processed is also significantly reduced. A few years later, in order to increase the ease of operation, DIENES invented the Quick Clamp system, which today has also become standard in many parts of the industry.

The DIENES cutting block Mini-Cut was a groundbreaking innovation for the tape and label industry. The cutting cassette realizes narrowest cutting widths and reduces set-up times by up to 90%. The cutting cassette is supplied by us as a completely assembled unit and, from a cutting width of 4 mm, ensures short set-up times and optimum accuracy. Offset, even a cutting width of 2 mm can be achieved. The Mini-Cut can be installed in all common machines and is also suitable for retrofitting. These are just a few proven solutions developed by DIENES together with the market leaders especially for cutting labels and adhesive tape.

We have also developed various methods that prevent the build-up of adhesive on the tools and minimize the loss of quality of the cut rolls. The special blade geometry as well as various coatings and cleaning devices can prevent the build-up of adhesives on the tools and the loss of quality of the cut rolls.

As an alternative to the crush cut, the shear cut can also be used for the production and processing of labels and adhesive tape. The photo shows, for example, the “Clean Cut” developed by DIENES, which uses process-dependent cooling during the cutting process to reduce material residues and adhesive buildup on the knife. Here, DIENES has developed a solution that quickly pays for itself in terms of longer machine running time, improved cutting edges and significantly reduced downtimes (cleaning times). In general, our knife holders of the “Ultimate” series have been specially developed for cutting label stock. In addition to simple depth adjustment features such as Senso Control, knife holder heads with integrated Constant Side Load technology or cleaning devices for continuous knife lubrication, we offer knives with specially polished surface finish. The surfaces of the dished knives are then provided with the DIENES special polish finish. The increased surface quality conditionally reduces the adhesion of the glue. Another option is a non-stick coating.

Matching DIENES products

-

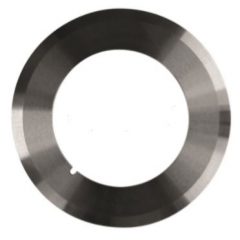

![The picture shows three different cutting rings from DIENES.]() Circular knives

Circular knivesCutting rings

Diameter 77-250 mmShow more -

![Circular knives - dished knives]() Circular knives

Circular knivesDished knives

Diameter 62-200 mmShow more -

![The picture shows DIENES grooved knives and multiple grooved knife blocks.]() Circular knives

Circular knivesGrooved knives

Diameter 46-250 mmShow more -

![DIENES multiple grooved knife blocks for an optimal cutting result.]() Circular knives

Circular knivesMultiple grooved knife blocks

Diameter 77-490 mmShow more -

![Shear cut pair of knives (collars) with knife carriers.]() Circular knives

Circular knivesCollars

Diameter 62-150 mmShow more -

![Spacers for top and bottom knives from DIENES.]() Circular knives

Circular knivesSpacers

Diameter 46-250 mmShow more