Shear cut

Shear cutting is known for its universal application. With this cutting process, very good cutting edge qualities are achieved in almost all industries, from paper, cardboard and paperboard, labels, adhesive tape, cable and litho tape, through aluminum, aluminum foil and non-ferrous metals, to film, foil, plastic, non-woven, textile, rubber and composites. And it does so with a wide variety of material types and thicknesses as well as high cutting speeds and a low level of cutting dust. It is also the best-known slitting technology for producing narrow strips from wide webs, which are then wound on a common winding shaft or separately on two winding stations.

Advantages of the shear cut are a high achievable cut quality, high cutting speeds and a low generation of cutting dust.

The shear cut can be performed in different variants:

- With two continuous shafts for top and bottom knife assembly.

- Mounting with only one continuous shaft for the bottom knives, while top knives are mounted from separate pneumatically operated holders.

- Mounting without continuous shafts. Here, top knives are mounted on individual holders and lower knives driven by electric motors.

Regardless of the most diverse designs, the shear cut is based on two overlapping knives.

DIENES Know-How

Depending on the material to be cut, the designs of the actual cutting tools differ. There are upper and dished knives with corresponding geometry. The counter knives are manufactured as cup knives and bottom knives or as slitting bush.

In pneumatically operated shear cut knife holders, the rotation of the top knife is effected by the friction of the driven bottom knife. This has a detrimental effect on the quality of the cut edges of very sensitive materials, for example papers of very small grammages such as cigarette paper, tea bag paper and aluminum foil. This is due to a certain amount of slip that is always present between top and bottom knives. These are special applications in which the use of motor-driven knives is recommended. This also applies to the cutting of thick cardboard and multi-layered papers, e.g. in sheeter cutters. Shear cut knife holders without their own drive can currently be used for papers up to a total basis weight of approx. 800 g/m² with a still acceptable cut edge quality. Alternatively, DIENES has developed the top to top cutting process, also known as the “twin cut” process.

Cross cutting knives

The shear cut process is also used in rotary cross cutters. In these, after the multi-ply paper webs have passed through the slitting section, the cross cut is made. The paper or cardboard webs are passed between two rotating cutting drums. The cross-cutting knives inside are installed in a spiral. Up to three knives are arranged on each drum. In the knife drum, the knife seat is enclosed in a spiral shape. The knives are straight and clamped by a plurality of clamping blocks, and the knives follow the twisted shape of the knife seat.

Matching DIENES products

-

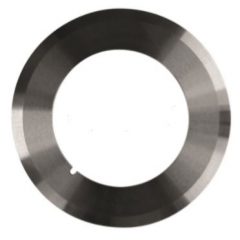

![The picture shows three different cutting rings from DIENES.]() Circular knives

Circular knivesCutting rings

Diameter 77-250 mmShow more -

![Circular knives - dished knives]() Circular knives

Circular knivesDished knives

Diameter 62-200 mmShow more -

![The goal of a DIENES knife is to achieve more performance, maximum tool life, minimum setup times and high cutting edge quality with minimum changeover effort.]() Circular knives

Circular knivesFlat top knives

Diameter 90-220 mmShow more -

![The picture shows DIENES grooved knives and multiple grooved knife blocks.]() Circular knives

Circular knivesGrooved knives

Diameter 46-250 mmShow more -

![DIENES multiple grooved knife blocks for an optimal cutting result.]() Circular knives

Circular knivesMultiple grooved knife blocks

Diameter 77-490 mmShow more -

![A DIENES bottom knife.]() Circular knives

Circular knivesBottom knives

Diameter 105-300 mmShow more

-

![Führungsleisten]() Straight knives

Straight knivesGuide rails

Show more -

![DIENES Straight knives for cutting.]() Straight knives

Straight knivesStraight knives for granulators and recycling

Show more -

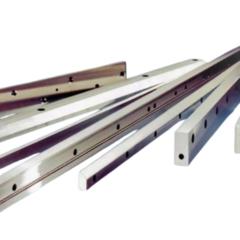

![Pictured is a DIENES straight knife range.]() Straight knives

Straight knivesCross cut knives and roll splitting knife

Show more -

![Pictured are scrap chopper from DIENES.]() Straight knives

Straight knivesShear blades and scrap chopper

Show more -

![Pictured is a range of paper cutting knives, tack cutter, three-knife trimmer and trimmer knife.]() Straight knives

Straight knivesPaper cutting knives, tack cutter, three-knife trimmer and trimmer knife

Show more