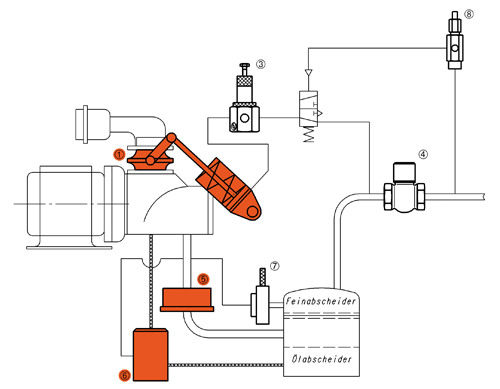

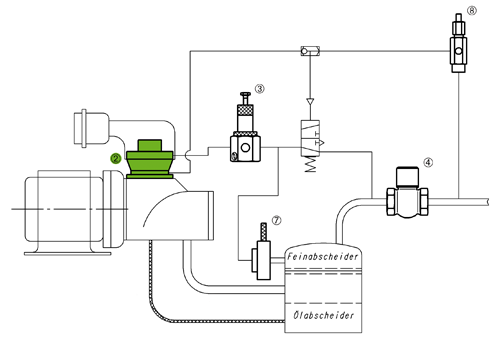

Products for oil-flooded rotary compressors (suction side with pneumatic control)

-

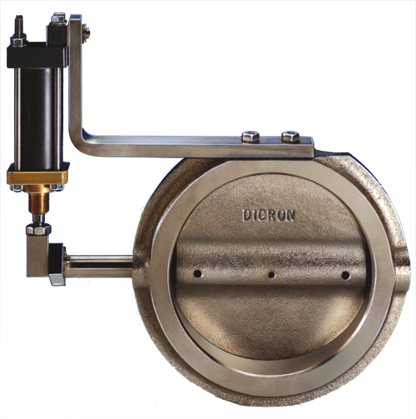

Throttle valve KN/ KP

DIENES throttle valves type KN are used to control the intake flow. They are closed at an angle to the inflow and form a metal seal with the housing. Shaft bearing by self-lubricating slide bushes.

Type KP is equipped with a pneumatic control cylinder.

Special feature here:

The control cylinder has a piston guide that is insensitive to dirt.

Combined with pressure ratio controllers type DV-N and DV-P, they allow stepless control of the suction volume depending on the final pressure.

Standard nominal sizes between 50 mm and 250 mm

Installation between flanges according to DIN 2501, PN6. -

Suction regulator ASE

When using oil-flooded screw compressor stages with pressure-resistant housing design and shaft sealing, it is possible to work with a control element which reliably and quickly closes the suction line in the event of backflow.

This prevents the oil/ air mixture in the compressor from escaping into the suction filter or the environment.

When such a closing device is used, the oil shut-off valve and the check valve become superfluous.

For this application the DIENES intake regulator type ASD (straight through) or ASE (angle) has been developed.This proven concept combines the control elements; suction throttle valve – oil shut-off valve – check valve – and bypass valve in one unit.

The DIENES suction regulators type ASD / ASE are flanged directly on pressure-tight screw compressor blocks. An intake air filter can optionally be screwed directly onto the intake regulator, or a hose line for an intake filter can be attached to the grommet provided.

Special features:

- Space-saving, compact design.

- Only one common control element for continuous delivery rate control and the non-return function.

- Operationally reliable in any installation position.

- In the event of reverse flow, the uniformly flowed and centrally guided valve plate closes reliably and quickly.

Three different control concepts possible:

- open-close control.

- Stepless control, positive-proportional (start-up of the compressor with the control element open).

- Stepless control, negative-proportional (compressor start-up with closed final control element).

- Teflon-guided actuator cylinder ensures smooth movement and minimal hysteresis.

- Integrated bypass valve (for negative-proportional control).

- Easy adaptation to different space conditions and compressor types possible.

DIENES suction controller type ASE2:

is a further development of the ASE series for direct installation on the pressure-resistant, oil-flooded screw compressor block with a fit optimized by angular shape for particularly tight installation conditions.

It is interference-optimized with optimum adaptation to the intended screw compressor block and can be adapted to all common screw compressor blocks. Additional connections for control and monitoring valves / sensors on request. -

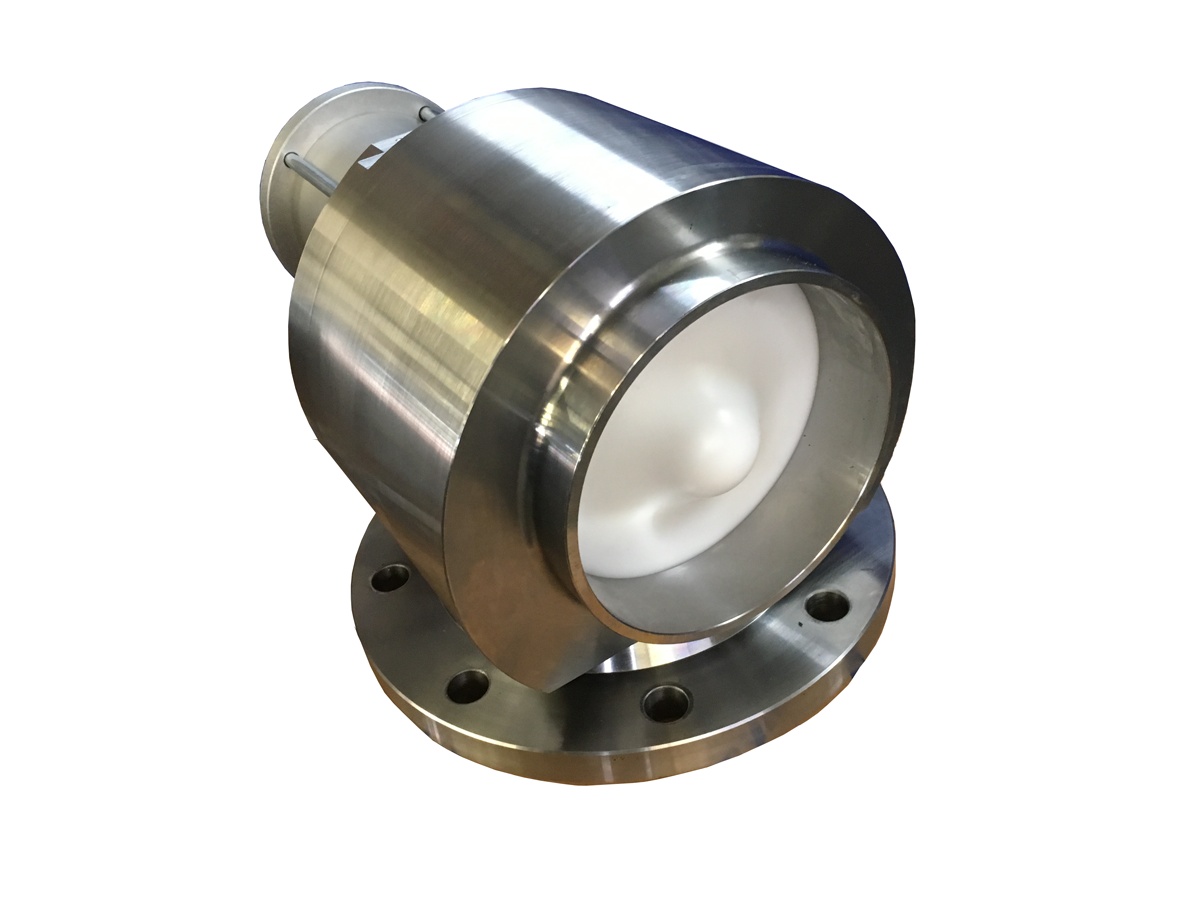

Ansaugregler ASD

When using oil-flooded screw compressor stages with pressure-resistant housing design and shaft sealing, it is possible to work with a control element which reliably and quickly closes the suction line in the event of backflow.

This prevents the oil/air mixture in the compressor from escaping into the suction filter or the environment.

When such a closing device is used, the oil shut-off valve and the check valve become superfluous.

For this application the DIENES intake regulator type ASD (straight through) or ASE (angle) has been developed.This proven concept combines the control elements; suction throttle valve – oil shut-off valve – check valve – and bypass valve in one unit.

The DIENES suction regulators type ASD / ASE are flanged directly on pressure-tight screw compressor blocks. An intake air filter can optionally be screwed directly onto the intake regulator, or a hose line for an intake filter can be attached to the grommet provided.

Special features:

- Space-saving, compact design.

- Only one common control element for continuous delivery rate control and the non-return function.

- Operationally reliable in any installation position.

- In the event of reverse flow, the uniformly flowed and centrally guided valve plate closes reliably and quickly.

- Three different control concepts possible:

- Open-close control.

- Stepless control, positive-proportional (start-up of the compressor with the control element open).

- Stepless control, negative-proportional (compressor start-up with closed final control element).

- Teflon-guided actuator cylinder ensures smooth movement and minimal hysteresis.

- Integrated bypass valve (for negative-proportional control).

Easy adaptation to different space conditions and compressor types possible.

DIENES suction controller type ASE2:

is a further development of the ASE series for direct installation on the pressure-resistant, oil-flooded screw compressor block with a fit optimized by angular shape for particularly tight installation conditions.

It is interference-optimized with optimum adaptation to the intended screw compressor block and can be adapted to all common screw compressor blocks. Additional connections for control and monitoring valves / sensors on request. -

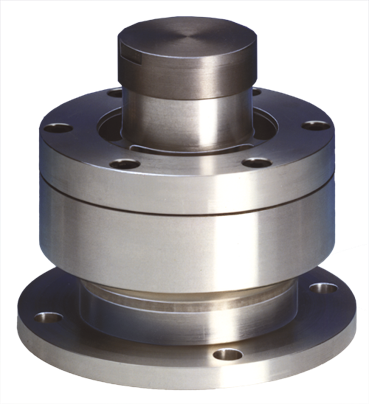

Pressure ratio controller

DV-N / DV-P

DIENES pressure ratio regulators with pneumatic control are used for capacity control of compressors when electronic control is not possible.

DIENES pressure ratio regulators are connected upstream of intake regulators and pneumatic control cylinders on throttle valves or pneumatically actuated actuators in the control of reciprocating compressors.

They continuously regulate the intake volume as a function of the final pressure.Special features:

- Positive-proportional (DV-P controller) or negative-proportional (DV-N regulator).

- The operating pressure is infinitely variable from the outside

- Sturdy, distortion-proof brass housing

-

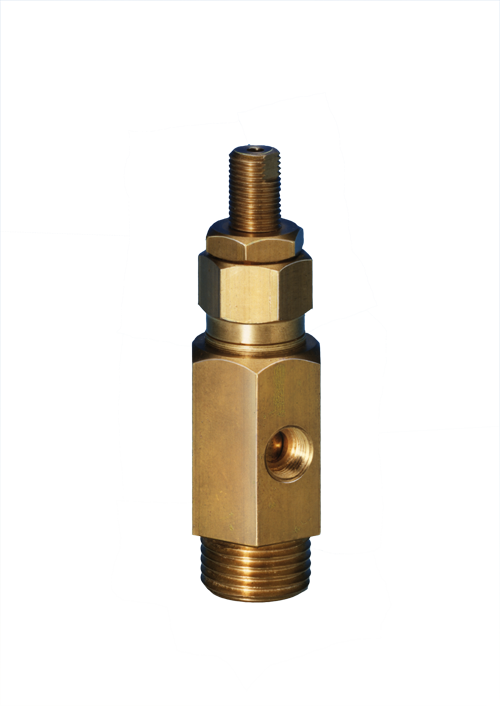

Intermittent controller ARK / ARH

DIENES intermittent controllers type ARK are used for load idle control.

Special feature:

Both switching points, the upper one for idling and the lower one for load running, are variable, independently adjustable.- The ARK version is intended for the normal pressure range – 12 bar.

- The ARH version is designed for the increased pressure range – 40 bar.