Products for oil-flooded screw blocks (pressure-side components)

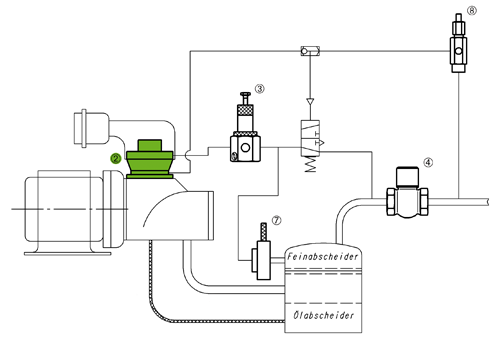

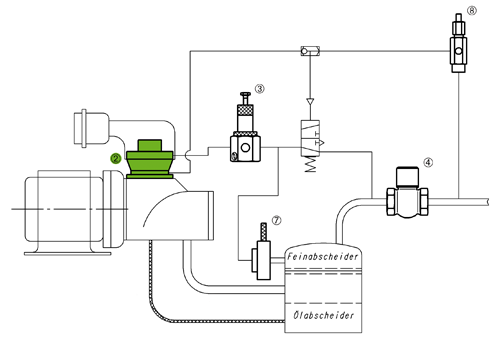

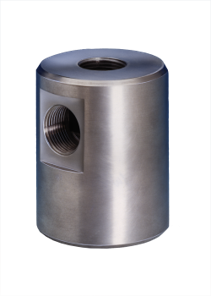

DIENES pressure maintenance valves type HS ensure the minimum pressure in the system required for operation in oil-flooded screw compressor systems.

A non-return valve is integrated into the pressure maintenance valves, which prevents backflow during control to zero delivery or machine stop.

The minimum pressure in the system can be set as standard in the range from 2.5 to 5 bar.

Available versions:

Special feature:

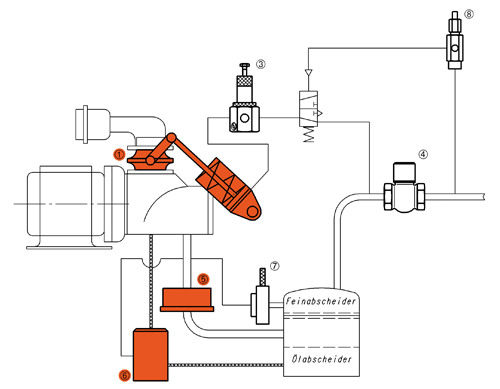

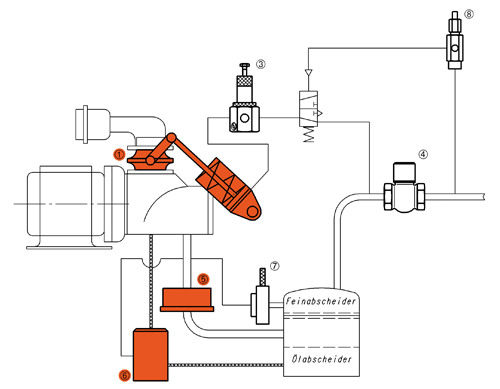

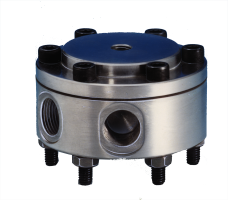

DIENES Oil stop valves or oil stop valves of the

reliably interrupt the oil circuit required for cooling and lubrication in load operation when the screw compressor is shut down.

This prevents the screw housing from being flooded with oil when the discharge pressure drops and prevents oil from escaping into the environment through the intake filter.

are used for automatic venting of the compressor system.

They are closed when the control pressure and system pressure are equal.

When the operating pressure drops, the machine is relieved.

Silencers can be provided on the machine side on a case-by-case basis.

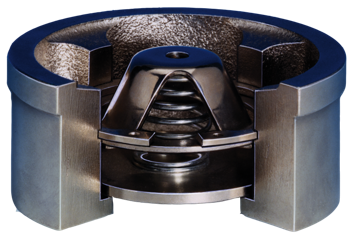

DIENES check valves type RN/ RS are used with oily and liquid media to protect against backflow.

The valve plate is spring-loaded so that it closes reliably even at low differential pressure.

Installation between flanges according to DIN 2501 PN6/ PN16. Available dimensions type RN from DN 25 to DN 125 and type RS DN 150.