Multiple grooved knife blocks

We are happy to offer you individual dimensions in addition to the standard ones.

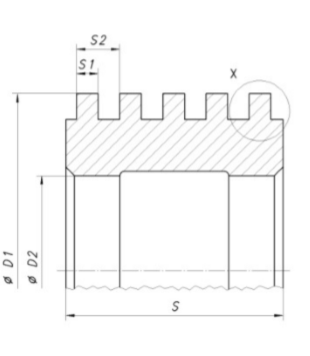

| Outer diameter | 77–490 mm |

|---|---|

| Inner diameter | 60–450 mm |

| Standard total strength | 50 / 100 mm |

| Standard cutting angle | 3° / 90° |

| Areas of application | Paper, cardboard, paperboard / labels, adhesive tape / aluminum foil, non-ferrous metals / film, foil, plastic / nonwoven, textile, special materials |

Multiple grooved knife blocks from DIENES

Precision and quality of the multiple grooved knife blocks are of great importance for the cutting result. Unusual precision requirements must be met during manufacture. The multiple grooved knife blocks itself, as well as its pitch, are manufactured to the tightest tolerances, ensuring consistently precise cutting widths.

DIENES manufacturing standards ensure optimum hardness, shape retention, lowest concentricity deviations, side impacts and surface roughness.

Use of multiple grooved knife blocks

A multiple grooved knife block basically has several cutting edges arranged on one or both sides. The multiple grooved knife blocks are located on an appropriately dimensioned shaft.

Multiple grooved knife blocks without locking are either clamped laterally on a bottom knife shaft by means of ring nuts or are mounted on an expansion shaft.

With the former design, one is bound by the respective cutting distances. When mounted on an expansion shaft, multiple grooved knife blocks are set to gap, allowing any cutting widths to be achieved.

By using multiple grooved knife blocks with screw locking, variable cutting widths can also be achieved.

All the variants mentioned are used in DIENES slitting and positioning systems. Two-piece multiple grooved knife blocks, with retaining ring or the patented hook fastener (type Duo-Ring) offer the advantage of quick multiple grooved knife block change without having to dismantle the bottom knife shaft assembly.

Your advantages

- Highest cutting performance due to optimised surface quality

- Precise manufacturing tolerances for use at high cutting speeds

- Different cutting groove pitches for the realisation of different cutting widths

- Can be used in shear and razor blade cutting

- Different locking options (smooth bore or screw locking)

- One-piece or two-piece versions

- Can be used for a wide range of machine types

- DIENES polish „CONTROLLEUR“

- Can be regrinded several times in manufacturer quality

Standard dimensions

Standard total thickness (S): 50 / 100 mm, standard groove width (S1): from 2.5 mm, standard pitch (S2): from 5 mm

Standard cutting angle: 3° / 90

Standard materials: chrome alloyed (1.5% Cr), high chrome alloyed tool steels (12% Cr)

Other dimensions and materials on request.

| Outer-Ø (D1) mm | Inner-Ø (D2) mm |

|---|---|

| 77 | 60 |

| 80 | 60 |

| 105 | 60 / 80 / 90 |

| 125 | 100 |

| 150 | 120 |

| 180 | 150 |

| 210 | 180 |

| 240 | 210 |

| 250 | 210 |

| 275 | 245 |

| 300 | 250 / 270 |

| 350 | 310 |

| 400 | 360 |

| 450 | 410 |

| 490 | 450 |