Circular knives

Whether made of steel, powder metallurgical steel (DPM), carbide, special materials or refined - our circular knives always stand for perfection. With up to 40 working steps, we use the latest technology to produce highly effective knives that impress with precise and clean cutting edges in long-term use.

DIENES circular knives are available for various applications up to a diameter of 500 mm.

Our large and continuously optimized standard program includes numerous upper and lower knives for shear, crush and burst cutting processes, matching high-quality cutting bushes for carrier and expansion shafts, as well as roller shear knives. We also manufacture knife sleeves, cutting and intermediate rings as well as glass hard shafts and rings with the highest quality.

In addition to our series products, we also manufacture circular knives that are developed exactly according to customer requirements for their special applications. Our comprehensive quality controls before delivery also guarantee that no tolerance deviations impair the performance of the cutting tools.

From standard products to individual special solutions, we can meet any cutting technology and customer-specific requirements.

Our circular knives

-

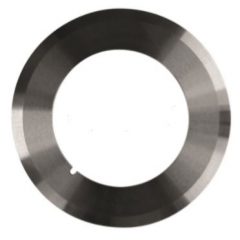

![The picture shows three different cutting rings from DIENES.]() Shear cut

Shear cutCutting rings

Diameter 77-250 mmShow more -

![Circular knives - dished knives]() Shear cut

Shear cutDished knives

Diameter 62-200 mmShow more -

![The goal of a DIENES knife is to achieve more performance, maximum tool life, minimum setup times and high cutting edge quality with minimum changeover effort.]() Shear cut, Twin Cut

Shear cut, Twin CutFlat top knives

Diameter 90-220 mmShow more -

![The picture shows DIENES grooved knives and multiple grooved knife blocks.]() Shear cut

Shear cutGrooved knives

Diameter 46-250 mmShow more -

![DIENES multiple grooved knife blocks for an optimal cutting result.]() Shear cut

Shear cutMultiple grooved knife blocks

Diameter 77-490 mmShow more -

![A DIENES bottom knife.]() Shear cut

Shear cutBottom knives

Diameter 105-300 mmShow more -

![Shear cut pair of knives (collars) with knife carriers.]() Narrow cut, Shear cut

Narrow cut, Shear cutCollars

Diameter 62-150 mmShow more -

![The picture shows the patented Golden Slit knife for narrow cutting.]() Narrow cut, Shear cut

Narrow cut, Shear cutNarrow cut with self-springing “Golden Slit” knives

Diameter 75-105 mmShow more -

![Spacers for top and bottom knives from DIENES.]() Narrow cut, Shear cut

Narrow cut, Shear cutSpacers

Diameter 46-250 mmShow more -

Shear cut

Tungsten carbide and ceramic knives

Show more -

![DIENES crush cut knives.]() Crush cut

Crush cutCrush cut knives

Diameter 50-150 mmShow more -

![Illustration of various circular knives including profiling knives and perforating knives from DIENES.]() Crush cut

Crush cutProfile and perforating knives

Diameter 50-150 mmShow more