Crush cut knives

Technical data

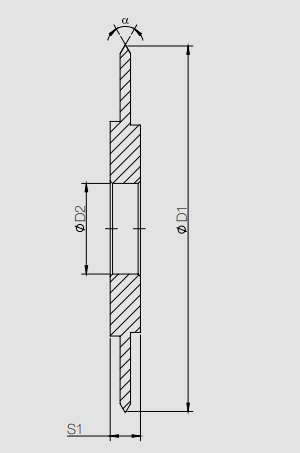

| Outer diameter | 50 – 150 mm |

|---|---|

| Inner diameter | 19 – 70 mm |

| Strength | 2,8 – 6,35 mm |

| Standard cutting angle | 30° / 45° / 60° |

Crush cut knives from DIENES

Crush cut knives bring with them easy handling of the tools and thus greatly reduced downtimes of the roll cutting machines. With regard to the cleanliness of the cutting edge, the application is limited to certain materials. Our scope of supply consits of customised perforating squeezing knives, profile squeezing knives in wave or zig-zag form and embossing rollers in a wide variety of designs. As standard materials we use chrome-alloyed (1.5 % Cr), high-chrome-alloyed tool steels (12 % Cr) and powder-metallurgical high-speed steels (DPM 23).

Use of crush cut knives

In crush cutting, the knive in the holder works under pressure against the glass-hard surface of a cutting shaft and cuts there, regardless of the setting of the bottom knive. Typically, the crush cut is used for cutting rubber, adhesive tapes, non-woven, tissue, emery and textiles, to name a few.

Your advantages

- Highest cutting performance due to optimised surface quality

- precise cutting edge geometry due to DIENES profile grinding process

- Cutting radii and angles adapted to a wide range of materials

- Can be used for a wide range of machine types

- Regrindable in manufacturer quality

Standard dimensions

Other dimensions and materials on request.

| Outer-Ø (D1) en mm | Inner-Ø (D2) en mm | Thickness in mm |

|---|---|---|

| 50 | 19 | 5,2 – 6,35 |

| 76,20 | 19 | 5,2 – 6,35 |

| 76,96 | 19/ 22 | 5,2 – 6,35 |

| 100 | 19 | 6,35 |

| 150 | 70 | 2,8 |

Cutting tests in our laboratory to determine the optimum design are also possible. From standard products to individual special solutions, we can meet any cutting technology and customer-specific requirements.