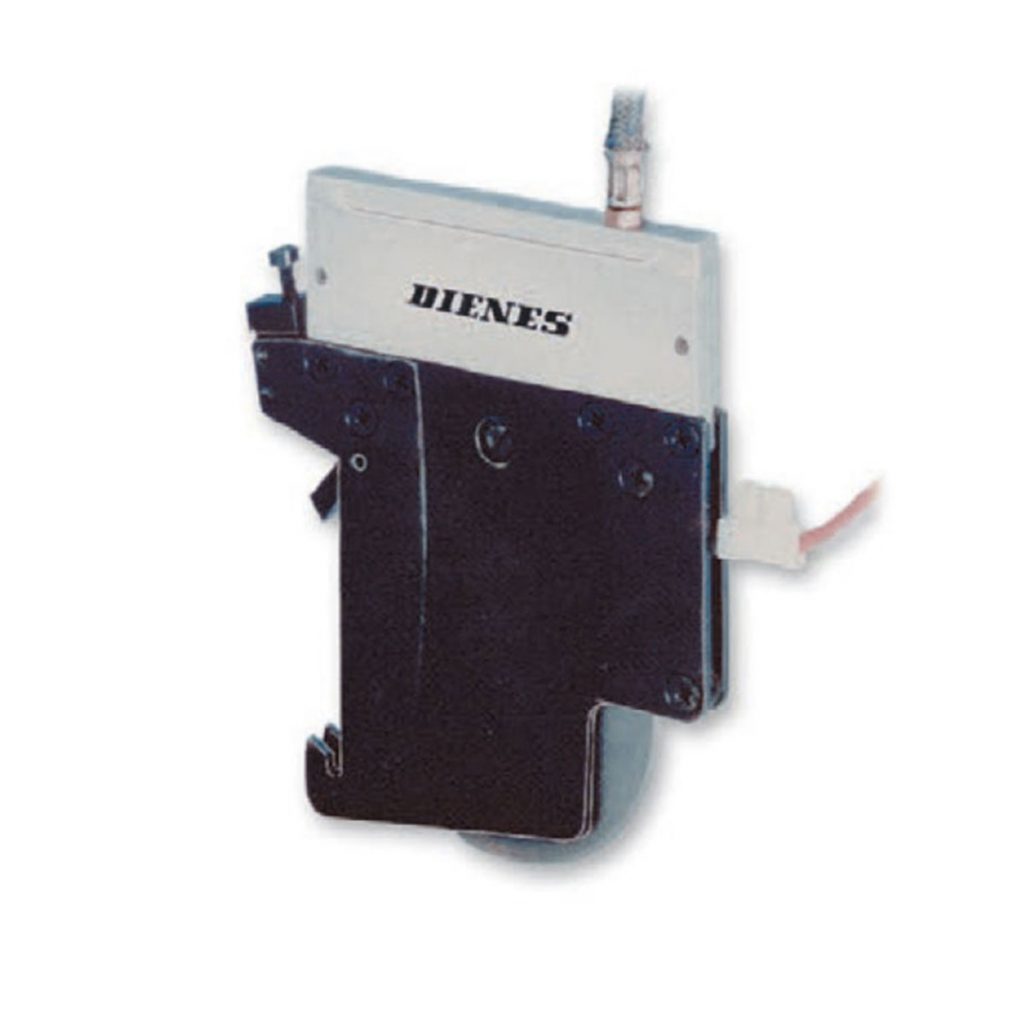

Knife holder PQAS H and PQDS H

Technical data

| Cutting width | smaller than 25 mm |

|---|---|

| Web speed | up to 70 m/min |

Heat cut knife holder from DIENES

The knife holders PQAS H and PQDS H were developed by DIENES for cutting synthetic fabrics. During hot cutting, the material to be cut is separated by high temperatures of up to 750°C and at the same time the cutting edges are welded.

The knife holder PQAS H and PQDS H offers the following additional functions

Operating comfort

Use of the knife holders PQAS H and PQDS H

The preferred areas of application for the knife holder include technical textiles. When the hot cutting element is heated up to 750 °C, this relatively high temperature separates the respective material to be cut and simultaneously welds the cutting edges. Depending on the material qualities, cutting speeds of up to 70 m/min are possible.

Version for the heated cut

In addition to the PQAS/PQDS H hot cut holder, a modification of the PQAS for heated cutting is also available from DIENES. In this case, the material is not cut by a hot cutting element, but by a crush cut knife heated up to 70°. The PQAS BH is used for processing paper and plastic films coated or impregnated on both sides with adhesive (hot melt adhesive) for label and sticker production. In the case of the previous slitting methods (crush and shear cut), the adhesive coating sticks to the knife edges and leads to web breaks and poor cutting edges in the short term.

Knives with a diameter of up to 90 mm can be used for this design, with a maximum cutting speed of 300 m/min.

We suggest you to send your slitting material to us and we will test in our cutting laboratory whether the cutting process is optimally suited for your application. Our cutting experts know their stuff and will be happy to advise you.

More impressions