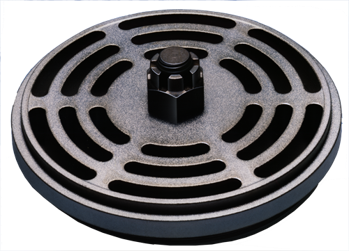

Concentric plate valves take into account the general development with regard to speed increase. By utilising the entire piston area, the largest possible free flow cross-section is achieved with a small stroke, a low gap speed and a favourable compressor delivery ratio. The valves are of a closed design towards the cylinder, which results in maximum operational reliability despite increased stress.

In air-cooled compressors, more intensive cooling is achieved by attaching cooling fins directly to the pressure valve body. The discharge valve plates consist without exception of individual rings which are loaded by impact- and noise-damping spring assemblies. Due to the more favourable flow compared to the off-centre single valves, the service life of the plate valves is extended.

Special designs with an extremely small clearance are also available on request.

Large gap cross-sections and thus low air velocities, as well as small dead spaces and thus a good degree of filling, guarantee the best utilisation of space. This results in a long service life of the plate parts, safety due to the closed construction and simple design of the cylinder head.

These advantages make the valves particularly suitable for installation in high-speed compressors with a small cylinder diameter in relation to the piston stroke.

Concentric valves with cooling fins.

This compact valve design with thermodynamic advantages over other designs is recommended due to favourable temperature transfer from the suction to the discharge section as well as to the outside. This ensures a long valve service life.

Special features:

- Large gap cross-sections and thus low air velocities

- Small damage spaces and thus good filling ratio

- Best space utilisation

- Long service life of the plate parts

- Safety due to closed design

- Simple design of the cylinder head

- For capacity control of the compressor available with lift-off gripper for valve plate control

- Valve and performance optimisation by computer simulation as a service for our customers.